Table Of Contents For This Page

Understanding premium connection options can be complex, so we have organized this page to help you easily navigate through the key details. Click on any section below to jump to the relevant information.

Common Uses:

- Oil, water, and gas transport in surface and downhole applications

- High-corrosion environments such as CO₂ and H₂S wells

- Wells requiring high wear resistance and flexibility

- Horizontal and directional wells

Polyethylene Lined Tubing

- Excellent wear resistance and flexibility

- High corrosion resistance, extending tubing lifespan

- Suitable for various oil, water, and gas well applications

Epoxy Powder Lined Tubing

- High resistance to acidic and alkaline environments

- Enhanced flow efficiency, minimizing friction loss

- Ideal for use in corrosive well applications

Tungsten Alloy Lined Tubing

- Corrosion resistance to CO₂, H₂S, and acids

- Heat resistance up to 600°C

- Suitable for demanding well conditions requiring superior protection

Stainless Steel Lined Tubing

- Strong bonding between liner and base pipe

- Long-term corrosion resistance for oil, water, and gas transport

- Ideal for use in both downhole and surface applications

Wanna deeper in Coating Pipe?

Step 1: Inquiry & Consultation (3-7 Days)

Step 2: Payment Confirmation (1 Day)

Step 3: Raw Material Sourcing & Preparation (7-28 Days)

Step 4: Manufacturing (15-45 Days)

Step 5: Testing, Packaging & Shipping (5-7 Days)

Want to Compress Lead Times?

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

What is the difference between BTC and LTC casing?

Differences Between BTC and LTC Casing and Their Applications Overview BTC (Buttress Thread Casing) and LTC (Long Thread Casing) differ in thread design, sealing performance, and load-bearing capacities, which makes them suited for distinct applications.

What are the different types of casing connections?

Types of Casing Connections Casing connections are essential in ensuring the integrity of well operations. Here are the primary types of casing connections: 1. API Standard Connections API (American Petroleum Institute) standard connections are widely

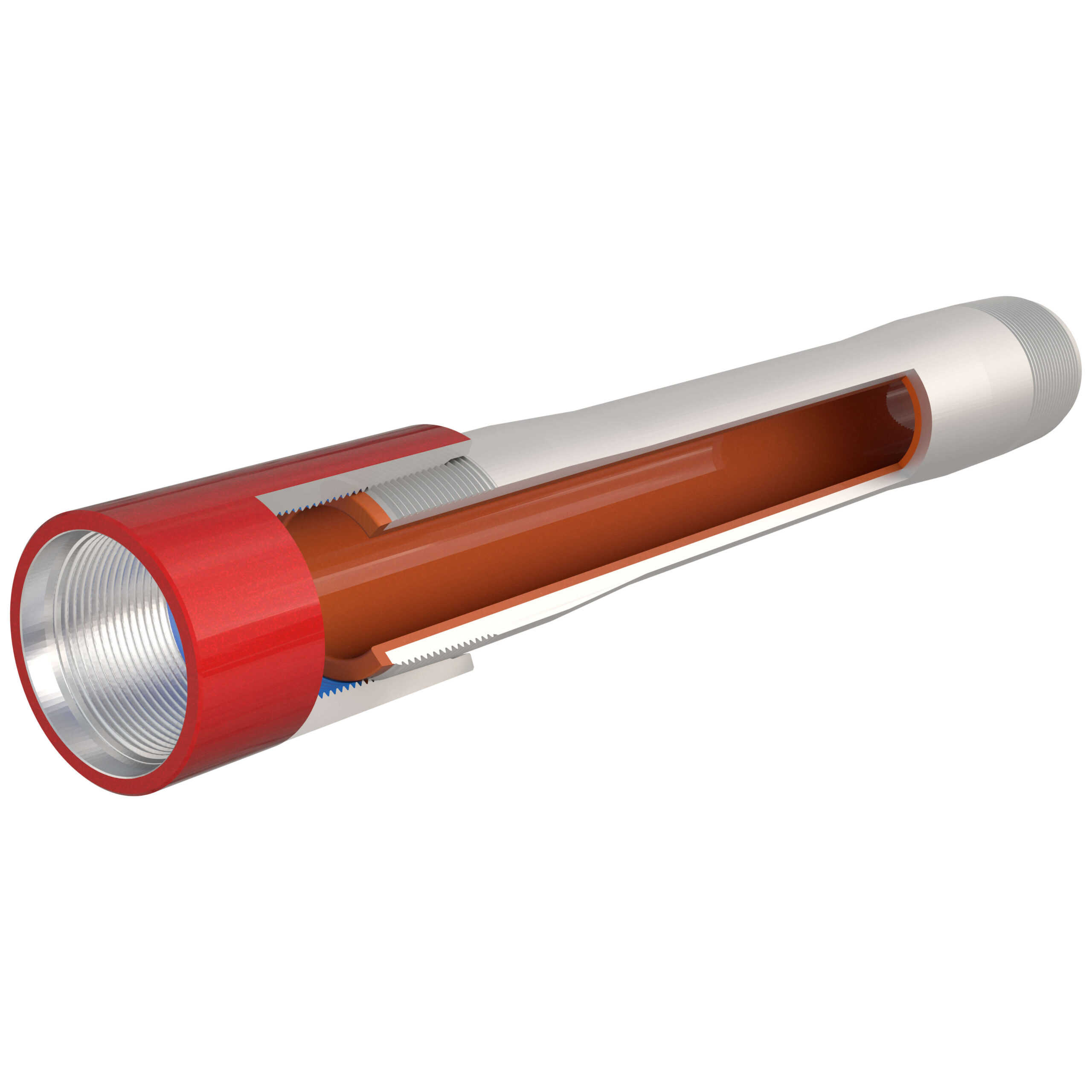

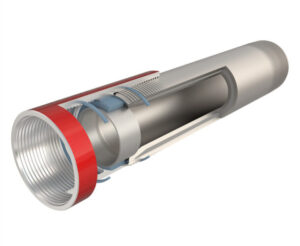

What is Premium Connection Casing?

Premium Connection Casing Premium Connection Casing refers to a type of oil and gas casing pipe with advanced threaded connections designed to provide superior performance in extreme conditions such as high pressures, high temperatures, and

What is vacuum thermal insulation?

What is Vacuum Thermal Insulation? Vacuum thermal insulation is a highly efficient insulation technology designed to minimize heat transfer. It is commonly utilized in high-vacuum insulated oil tubing, which is specifically engineered for heavy oil

What is the thermal conductivity of vacuum insulated tubing?

Thermal Conductivity of Vacuum Insulated Tubing The thermal conductivity of vacuum insulated tubing (VIT) is extremely low, close to zero. This is because the core principle of vacuum insulation is to create a vacuum (a

What is a premium connection?

What is a Premium Connection? A premium connection refers to a high-performance joint or coupling used to connect sections of pipe or tubing, especially in industries like oil and gas, drilling, and production operations. These

What is VIT Tubing? A Guide to Cryogenic Insulation

VIT Tubing (Vacuum Insulated Tubing) VIT tubing stands for Vacuum Insulated Tubing, a type of piping designed to transport extremely cold fluids or gases, particularly in cryogenic applications. The tubing is designed with a vacuum

Top 10 Questions to Ask When Buying Vacuum Insulated Tubing (VIT)

When purchasing vacuum insulated tubing (VIT) for oil, gas, or geothermal applications, it’s crucial to ensure you’re getting the right product for your specific needs. Below are the top 10 questions you should ask to

What is the vacuum insulated tubing?

Vacuum Insulated Tubing (VIT) is a specialized product designed to maintain temperature control in challenging environments, primarily used in the oil, gas, and geothermal industries. It consists of an inner and outer tubing with a

- Risk of Specification Mismatch

- Non-compliance with Quality Standards

- Overlooking Delivery Timeframes

- Neglecting Long-term Durability

- Unclear Customization Requirements

When selecting a partner for lined tubing solutions, it’s important to choose a provider that not only offers high-quality products but also understands the complexities of your operations. Meshine Thermal stands out for its commitment to excellence, precision engineering, and a customer-first approach. Our products are rigorously tested and certified to meet international standards, ensuring they perform reliably in even the most demanding environments.

From our state-of-the-art production facilities to our global expertise, Meshine Thermal has successfully supported oil and gas projects worldwide. Whether you require customized solutions or standard products, we deliver on time and with unparalleled quality.

- Global Expertise: Supplying premium connections to major oilfields across North America, Europe, the Middle East, and beyond.

- Certified Quality: All products meet API, ISO 9001, and ISO 14001 standards, ensuring compliance and reliability.

- Customer-Centric Approach: We work closely with you from consultation to delivery, ensuring that your specific needs are fully addressed.

Meshine Thermal is dedicated to driving operational efficiency for our clients by delivering premium connections that reduce downtime and enhance safety, making us the trusted partner for oil and gas companies around the world.