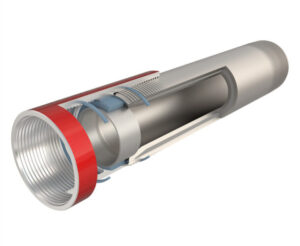

Thermal Conductivity of Vacuum Insulated Tubing

The thermal conductivity of vacuum insulated tubing (VIT) is extremely low, close to zero. This is because the core principle of vacuum insulation is to create a vacuum (a space with little or no matter) between two layers of material. In a vacuum, there are very few molecules to conduct heat, which significantly reduces heat transfer.

Key Points:

- Thermal conductivity of vacuum: The thermal conductivity of a vacuum itself is virtually zero, as heat conduction relies on particles (such as air molecules) to transfer heat, and in a vacuum, there are no particles to facilitate conduction.

- Conduction and convection: Heat transfer through conduction and convection is almost entirely eliminated, which is why vacuum-insulated products, such as vacuum-insulated tubing, are highly effective at maintaining temperature stability.

- However, radiation (infrared heat transfer) still occurs in a vacuum, but vacuum-insulated tubing typically includes a reflective layer to reduce heat loss due to radiation. This helps further minimize heat transfer.

Typical Values:

- The thermal conductivity of vacuum-insulated tubing typically ranges from 0.001 to 0.01 W/m·K (Watts per meter per Kelvin), which is extremely low compared to other materials.

- This value can vary slightly depending on the quality of the vacuum, the material used for the inner and outer layers, and the presence of any reflective coatings.

Comparison:

For context, common insulation materials like fiberglass or foam typically have a thermal conductivity range of 0.03 to 0.04 W/m·K, making vacuum insulation much more effective at reducing heat transfer.

In summary, vacuum-insulated tubing offers exceptional thermal insulation due to the very low thermal conductivity of the vacuum layer, which minimizes heat transfer through both conduction and convection. The addition of reflective coatings further helps reduce heat loss via radiation.