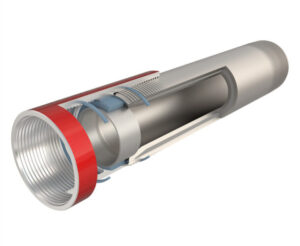

Vacuum Insulated Tubing (VIT) is a specialized product designed to maintain temperature control in challenging environments, primarily used in the oil, gas, and geothermal industries. It consists of an inner and outer tubing with a vacuum space between them, which significantly reduces heat transfer. This design ensures better insulation than conventional tubing, helping to minimize heat loss or heat gain in applications such as heavy oil recovery, high-temperature wells, and geothermal energy development.

Key Features and Benefits of Vacuum Insulated Tubing:

-

Thermal Efficiency: The vacuum layer between the inner and outer pipes prevents conduction and convection heat transfer, ensuring high thermal insulation performance. This helps to keep fluids at the desired temperature throughout the transportation process.

-

Applications:

- Heavy Oil Recovery: VIT is used in thermal recovery processes like steam-assisted gravity drainage (SAGD) or cyclic steam stimulation (CSS), where heat must be retained in the injected steam to maximize oil recovery.

- Geothermal Energy: In geothermal wells, VIT minimizes heat loss, enhancing the efficiency of energy extraction.

- Offshore Oilfields: It is used in subsea production where temperature maintenance is crucial.

-

Durability: VIT is designed to withstand extreme environmental conditions, including high pressure and corrosive substances found in oil fields.

-

Cost Efficiency: By improving heat retention, VIT reduces the energy costs associated with re-heating fluids or maintaining temperatures, which translates to lower operational costs over time.

Why we need Meshine VIT?

Meshine's Vacuum Insulated Tubing (VIT) products are recognized for their high performance and reliability. The company utilizes advanced manufacturing techniques and quality assurance processes to ensure their VIT products meet international standards. Their VIT is widely used in heavy oil recovery, geothermal projects, and offshore oilfields, contributing to improved energy efficiency and technical innovation.