VIT Tubing (Vacuum Insulated Tubing)

VIT tubing stands for Vacuum Insulated Tubing, a type of piping designed to transport extremely cold fluids or gases, particularly in cryogenic applications. The tubing is designed with a vacuum between two layers of material to provide excellent thermal insulation, preventing heat transfer.

Key Features

1. Vacuum Insulation

VIT tubing consists of two concentric tubes, with a vacuum space between them. This vacuum layer acts as a highly efficient thermal insulator, reducing heat transfer via conduction or convection, and helps maintain the temperature of the fluid inside the inner tube.

2. Cryogenic Applications

VIT tubing is commonly used to transport cryogenic fluids such as liquid nitrogen (LN2), liquid oxygen (LOX), liquefied natural gas (LNG), and other extremely cold substances. The insulation helps prevent the fluid from evaporating or warming up during transport.

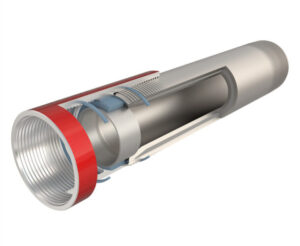

3. Structure

- Inner Tube: This carries the fluid (e.g., liquid nitrogen or gas).

- Outer Tube: Acts as a protective layer.

- Vacuum Space: The area between the inner and outer tubes, evacuated of air to create the vacuum insulation.

Applications

- Cryogenics: VIT tubing is used in industries that require the transport of cryogenic fluids, such as in medical gases, chemical industries, research laboratories, and energy (LNG).

- Industrial & Laboratory Use: Used in systems where maintaining the temperature of transported liquids or gases is crucial, such as in liquid gas storage or scientific experiments.

Benefits of VIT Tubing

- Temperature Control: It helps keep transported fluids or gases at low temperatures for extended periods, reducing the need for external refrigeration.

- Energy Efficiency: By preventing heat loss, VIT tubing reduces energy consumption and helps in the efficient handling of cryogenic fluids.

- Safety: Reduces the risk of temperature-related accidents or contamination.

In short, VIT tubing plays a critical role in ensuring the safe and efficient transportation of cryogenic fluids by maintaining the low temperatures required for their storage and transport.